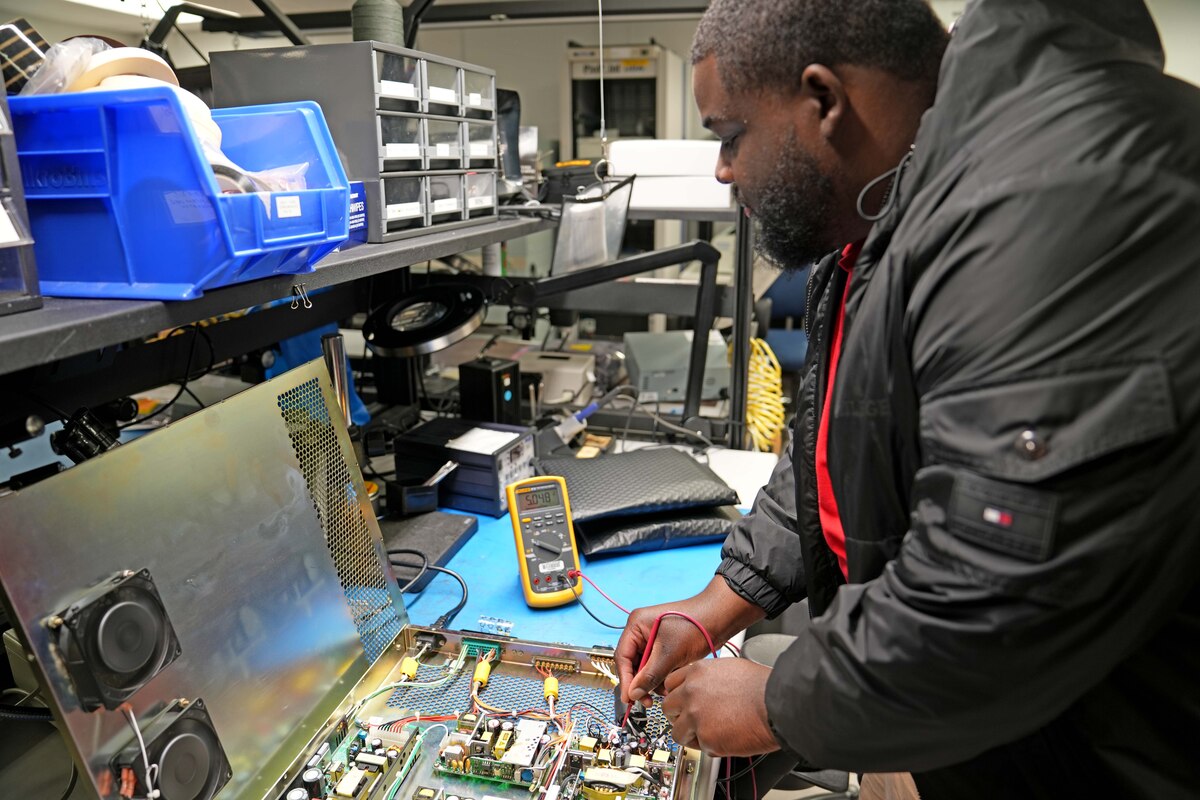

Joseph Mather

In a world of rapidly evolving technology, keeping older aircraft and systems operational can be a significant challenge.

That's where the 402nd Electronics Maintenance Group Reverse Engineering, Avionics Redesign, and Manufacturing, or REARM, lab at Robins Air Force Base, Georgia, steps in.

Rob Taveras, 402nd EMXG REARM director, said the unique lab plays a crucial role in sustaining U.S. airpower by tackling obsolescence and ensuring warfighter readiness.

"We develop innovative ideas and deploy cutting-edge aerospace avionics technologies to ensure warfighter readiness," he said. “While the lab refines technical data it also engineers seamless forms, fit and function interface replacements.”

The REARM lab’s mission is to provide design solutions for outdated or obsolete electronics.

The lab is comprised of program managers, electronics and mechanical engineers, drafting specialists, and depot maintenance contract augmentees and is broken down into three elements: reverse engineering, avionics redesign and manufacturing. Each element supports the others when needed but also has their own niche mission objective.

Tristan Griffin, 402nd EMXG electronics engineer, said the hybrid lab is the only one in the Department of Defense and was around before REARM became a combined section

“REARM provides a wide range of advanced avionics capabilities, including precision hybrid microcircuit manufacturing, avionics reverse engineering, development of interface test adapters, creation of avionics technical data packages, in-depth diagnosis and repair, avionics redesign, prototype development and qualification testing,” he said. “They even offer end-to-end design and reverse engineering of complete avionics systems.”

Another critical component of REARM is the hybrid lab, a certified 10K cleanroom facility authorized to manufacture hybrid microcircuits in a dust and dirt-free environment that ensures circuits remain clean during the build process.

“These miniaturized electronic circuits combine different components onto a single substrate,” he said. “The hybrid lab can perform both reverse engineer and avionics redesign on microelectronic chips as well as manufacture the chips for the asset owner.

“Think of a hybrid component as a miniature circuit card, same components and purpose, just smaller,” he continued. “The hybrid lab can support any hybrid component. Since the data is usually incomplete for the cards, that means the hybrid lab must first reverse engineer the component. If any parts are obsolete, they must redesign it much like avionics redesign and then manufacture the new chip.”

In continuous operation since the mid-1980s, the hybrid lab supports all aircraft platforms, as well as automated test equipment, digital mapping systems and radar warning receivers’ line replaceable units.

Taveras said the REARM lab takes critical projects that major defense contractors often pass over due to limited profit margins.

"We can do components that go directly onto the airframes, components found in line replaceable units, components in testers, and even components found on individual circuit cards," he said. “Where others see low return, we see mission importance committing our expertise to ensure no capability gap is left unaddressed."

The lab maintains an organic approach, minimizing costs while delivering long-term support for legacy weapon systems.

"Often, mission partners turn to us as the sole source of viable solutions," Taveras said.

"If REARM wasn’t here, then any workload would have cost several times more in the private sector to be accomplished, or, at the worst, that asset would not be supportable and the warfighter would be down that capability,” said Griffin.

Taveras, who has been with the organization since 2004, said he’s witnessed significant changes and mission successes.

"REARM is more than a workspace, it’s a dynamic environment where engineering challenges fuel innovation," he said. "I've had the rewarding experience of seeing new capabilities take shape and contribute to the full lifecycle of next-generation avionics systems."

"I’ve worked on assets made in 2022 and I’ve worked on assets made in 1958, so I’ve seen how every mission is different. It’s rewarding to know I can be a part of keeping those assets going another 50 years, if need be,” Griffin added.

Both Taveras and Griffin expressed deep pride in knowing their work directly strengthens and sustains the mission of the warfighters.

"Being a critical force behind their success isn’t just rewarding, it’s what drives us every day,” said Taveras.